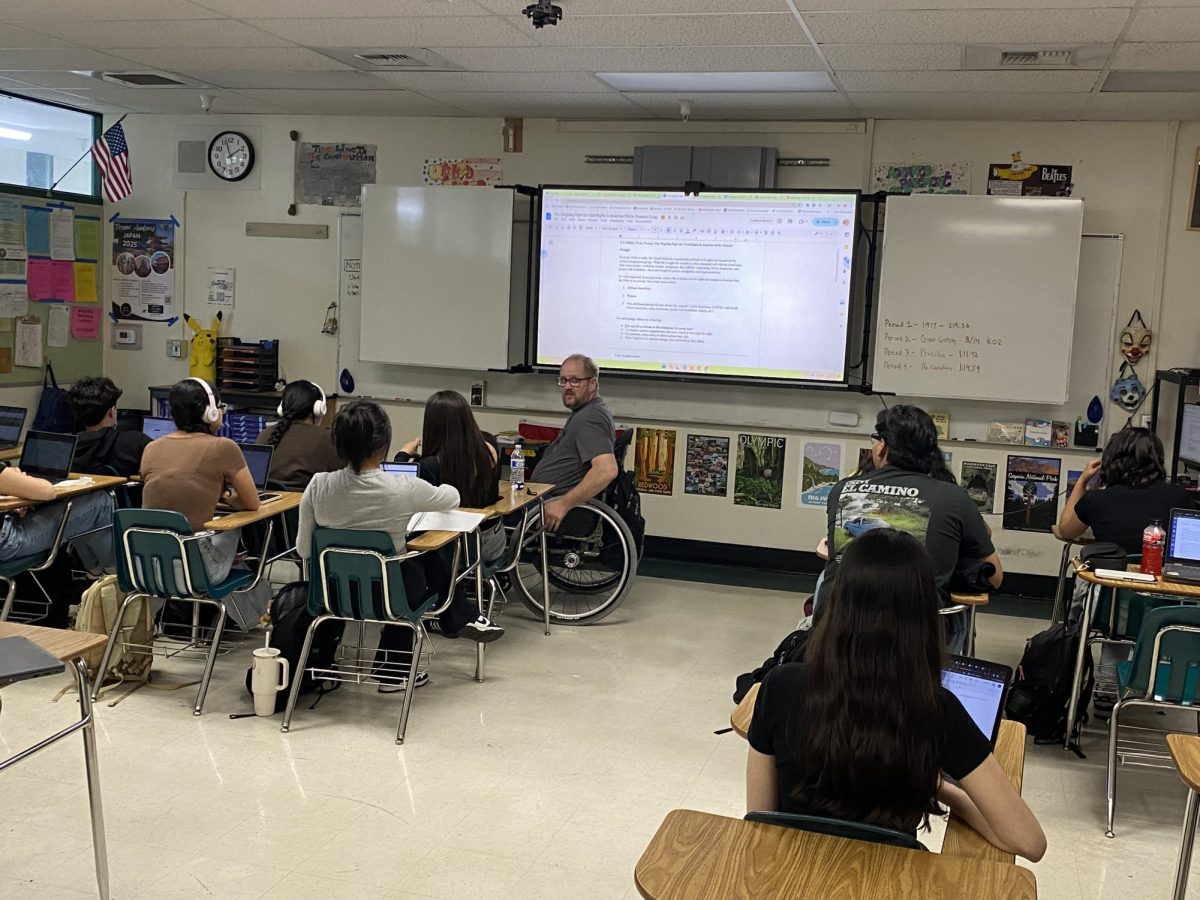

The engineering academy hasn’t been short of awards in the past year. They’ve won the NPS design challenge in back-to-back years. However, this year was different for one reason. “During the award ceremony we were told by the event organizers, naval postgraduate school employees, that they were one of the best in the nation,” Lorand Incze, the Engineering Academy advisor and engineering teacher, said. “The ingenuity that the students had…They invented a robot that cleans, and then paints the hull of a ship. The additional feature of painting was their idea.”

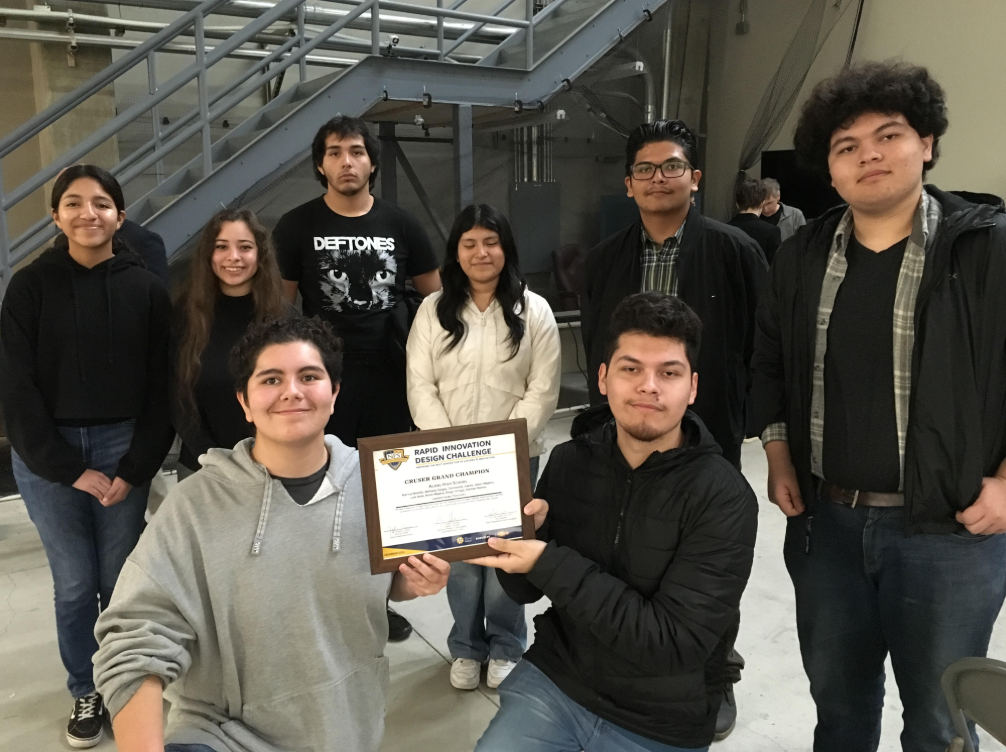

The team consisted of three grade levels: three seniors – Marisol Botello, Dannadely Juarez-Hernandez, and Bethany Vargas; three juniors – Jason Majano, Damian Ramos-Gomez, Luis Ante; and two sophomores – Diego Ortega, and Kevin Majano. . The group designed a robot that removes bio-foul (algae, seaweed, barnacles) from the hulls of ships. “Our project was to build an underwater robot to clean the hulls of ships, big military ships, and it had to clean bio-foul on used sections,” Botello, a 4th year engineering student, said. “The robot brushes UV light to weaken biofoul and also uses a preventative spray so bio-foul wouldn’t grow again.” It’s an important tool because “it [bio-foul] slows them down which impedes their efficiency and makes them go slower in the water,” Majano said.

The reason why the group chose a biofoul removing robot for their NPS design project is because naval fleets in Monterey Bay want to respond quicker to emergencies. “If they can’t respond as early, that could be an issue for any emergency that they’re dealing with,” Ramos-Gomez said.

So, how does the machine work? “It works off a couple motors mainly,” Ante said. “It usually suctions to the bottom of the boats. It uses a bunch of brushes to scrub off all kinds of biofoul that you can find along the hulls of boats and uses paint to repaint boats.” The project started in September, ended in December, and along the way the team encountered many challenges. “I will say that we were stressed on deadlines,” Botello said. “Sometimes we’d come in after school to finish whatever we’re working on, so we had extra time to finish it.”

Another challenge the group faced was generating a design for their robot, which they’d create physically. “I think not knowing where to start and having to generate all these ideas was difficult,” Vargas said. The team had to scour the internet for existing machines in action, but ultimately ended up with a design.

Although the challenges pushed the group out of their comfort zone, the group had proud moments.” I think the proudest moment we had was when we 3-D printed, copied the design, and then we started working on it to make it effective, and actually made it functional,” Ramos-Gomez said. “That was our proudest moment because we got to see how our creation worked, if we actually created it, as intended. And it was cool to see how it could work in a real life setting.”

As a result of the project, the group knows their communication skills have improved and they believe in themselves to accomplish more in their future. “The teamwork of the group was exceptional as they were able to coordinate among themselves to divide and complete the work,” Incze said. “I learned to be patient with myself and with others. I clearly stated what needs to be done and helped out if they had any questions because it’s a very complicated process,” Botello said.

“Winning the NPS design challenge, I think, had a profound effect on me and my teammates because it was the first thing I actually accomplished this year then in the previous years,” Vargas said. On top of developing invaluable skills, virtues, and the belief in themselves to succeed in the future, the group won a $1,500 stipend, a microcredential, and were congressionally recognized. “The group will use the money to buy soldering equipment,” Incze said.

![Senior Jayden Duarte dives across the goal line for one of his five touchdowns in a dominant 62-40 victory over Monterey. It has been a highly successful season for Duarte, and he credits his coaches for putting him in positions to succeed and make key plays. “The goal is to help wherever the coaches need me, receiver, running back, [and] DB,” he said.](https://alisaltrojantribune.com/wp-content/uploads/2025/10/IMG_3599-2-1200x800.jpg)